PT Toba Pulp Lestari produced 200.192 tons of pulp in 2021.

Management of Plantation Forest

The management of PT Toba Pulp Lestari Tbk (“the Company”) believes that accountable forest management, taking into account environmental risk, makes a positive contribution to the business and is beneficial to employees, customers, shareholders, and other stakeholders. The company also believes in a sufficient environment policy and implementation of a sustainable forest management strategy, including:

Production Process

As part of our commitment to environmental management, we aim to improve in all environmental aspects, including emissions, waste water management, solid waste management, and management of resources such as water, energy conservation, and timber consumption.

Emissions are monitored by six Continuous Emission Monitoring (CEM) devices installed at the recovery boiler, multifuel boiler, common stack recovery boiler, bleaching plant, incinerator and lime kiln.

All equipment is maintained, cleaned and calibrated according to a schedule, and manual testing is carried out regularly by an external laboratory.

- Reducing emissions from causticizing and lime kiln of TRS by 5%, fine particles by 26% and opacity by 29% compared to 2014.

- E Reduced HCL emissions by 16% and slaker vent particles by 18% from Chemical Plant Reduction compared to 2014 levels.

Products

PT Toba Pulp Lestari Tbk is a producer of industrial pulp or commonly known as pulp. Its product is sold at the domestic and export markets. Total production of last year (2021) reached 200.192 tons.

Awards

Jamsostek

Company of the Year 2005

Best Entrepreneur of

Women Workers 1996

Sahwali Award

Industri Hijau 2018

LEMHANNAS 2003

PROPER Awards 2019 - 2020

PANPEL Study

Excursie Science 1991

ASEAN Institute of

Forest Management

Certification

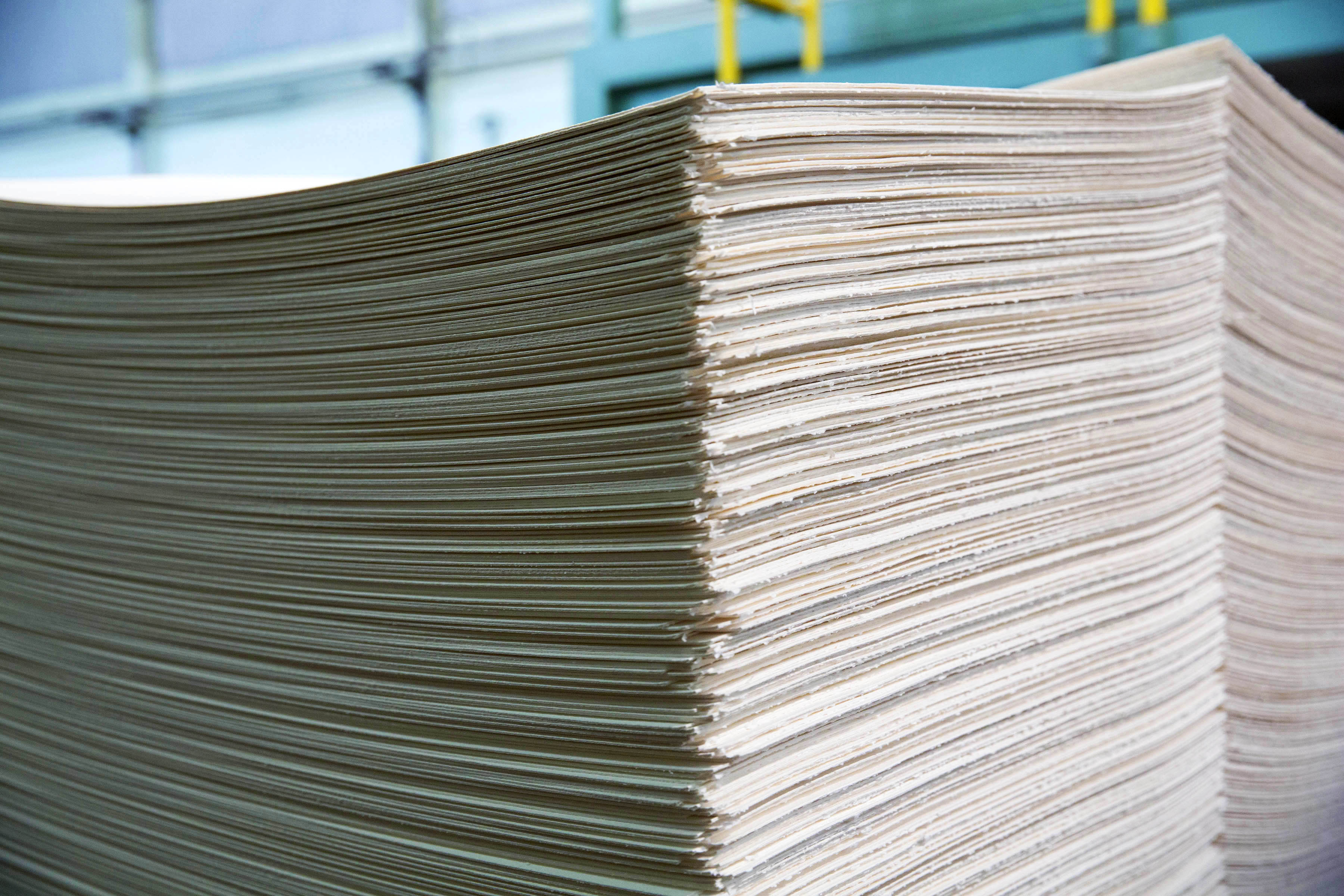

PEFC

PEFC - Chain of Custody Certification from SGS Certification Body for the scope of activities: The purchase of PEFC certified and non-controversial Pulpwood, for the manufacture outsourced warehouse management and sale of PEFC Certified Pulp and PEFC Controlled Sources Pulp using the percentage based method (Section 6.3) and based on Appendix 1 (Specification of the PEFC claims) and appendix 2 (Multisite management system) of the chain of custody standard, obtained for the first time since 20th March 2018. Certificate Number: SGSCH-PEFC-COC-440006, valid until March 19th, 2028

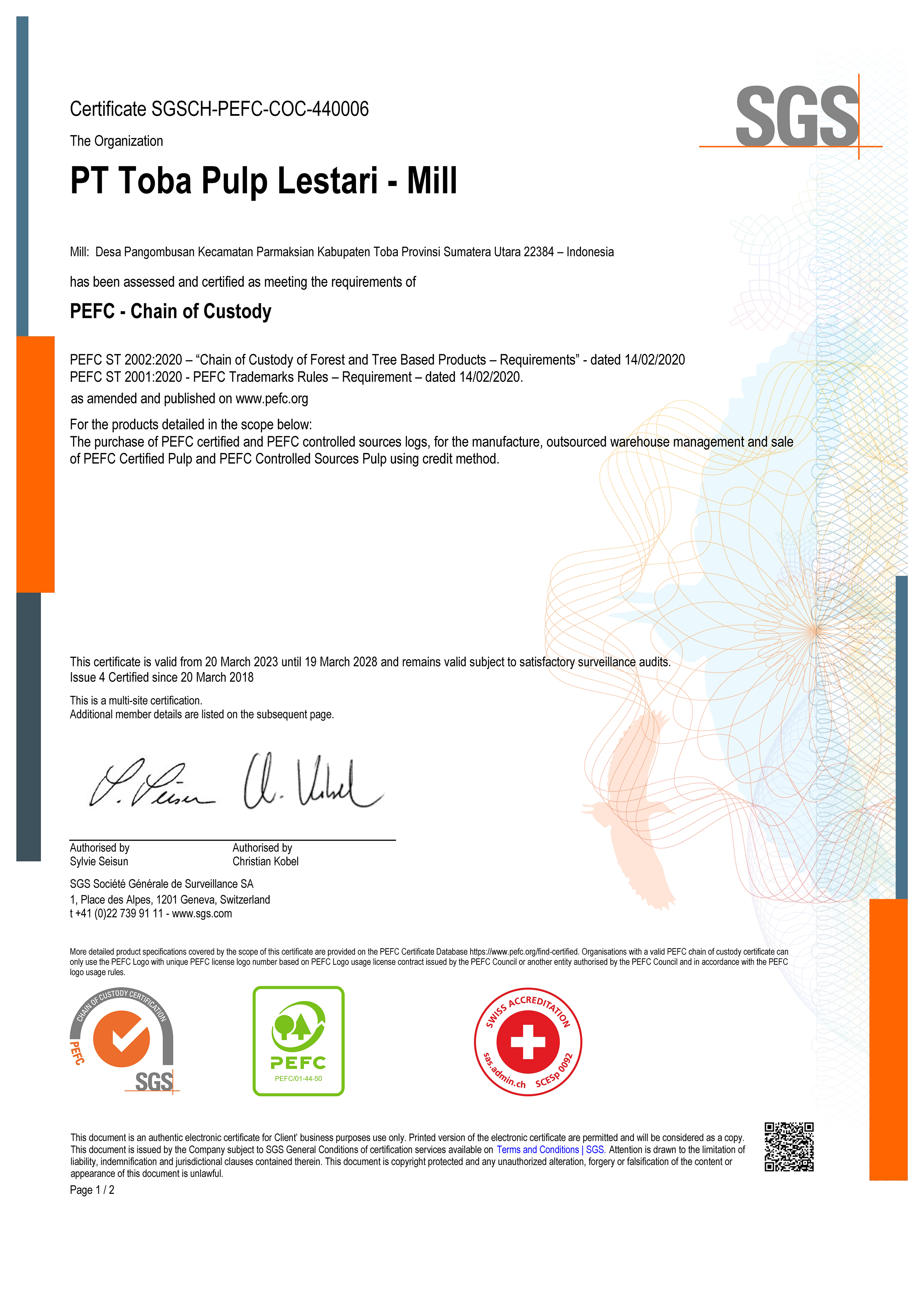

IFCC

This IFCC certificate proves that the sustainable management of industrial plantation forests (HTI) provides a guarantee to consumers throughout the world that PT TPL provides sustainably managed forest products whose implementation meets the PEFC sustainable forest management benchmarks. By obtaining IFCC certification which is the result of verification by the Bureau Veritas Indonesia certification body, it shows that TPL carries out operational activities by considering friendly production aspects, paying attention to ecological and environmental aspects and synergy with the community as an implementation of social aspects in carrying out forest management in a sustainable, balanced, and sustainable manner. and sustainable. Valid until 2026.

SMK3

Recertification of the SMK3 audit in the Occupational Safety and Health Sector for Forestry Pulpwood Production Plantations on 03-06 October 2022. With the results: "The level of K3 implementation reached a percentage of 94.57% and was included in the "Satisfactory" implementation category which was verified directly by the Sucofindo certification body and has valid until 2025.

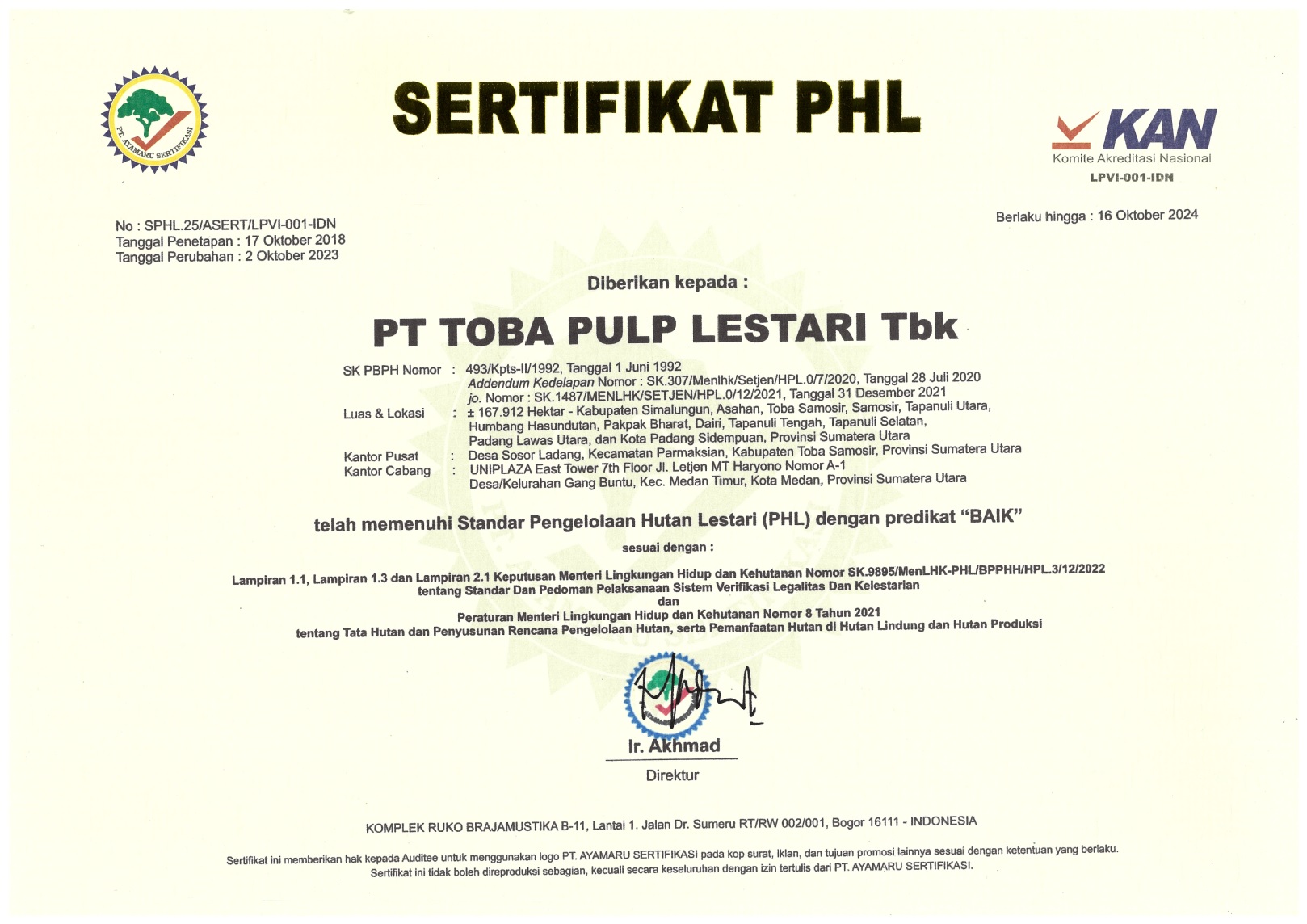

PHL

Sustainable Forest Management is a certification that contains the basic principles of sustainable forest management in the form of good forest governance, representation and management transparency. It is a certification that is mandatory or mandatory based on the demands of the national market or market griven which is carried out in accordance with timber legality verification standards based on applicable laws and regulations and aims to maintain and increase the economic, social and environmental value of forest resources as verified by a verification assessment agency. independent Ayamaru Certification. SK.9895/MenLHK-PHL/BPPHH/HPL.3/12/2022 and has valid until October 16, 2024.

SVLK PKR

Timber Legality Verification Certification (VLK) from the SGS Certification Agency for scope of activity: PT. Toba Pulp Sustainable Plasma Community Timber Plantation with 958 plasma member farmers with a total area of 4,312 hectares. This certification is a certification based on standards listed in government regulations whose implementation uses the Decree of the Indonesian Minister of Environment, which has a validity period until 11 May 2027.

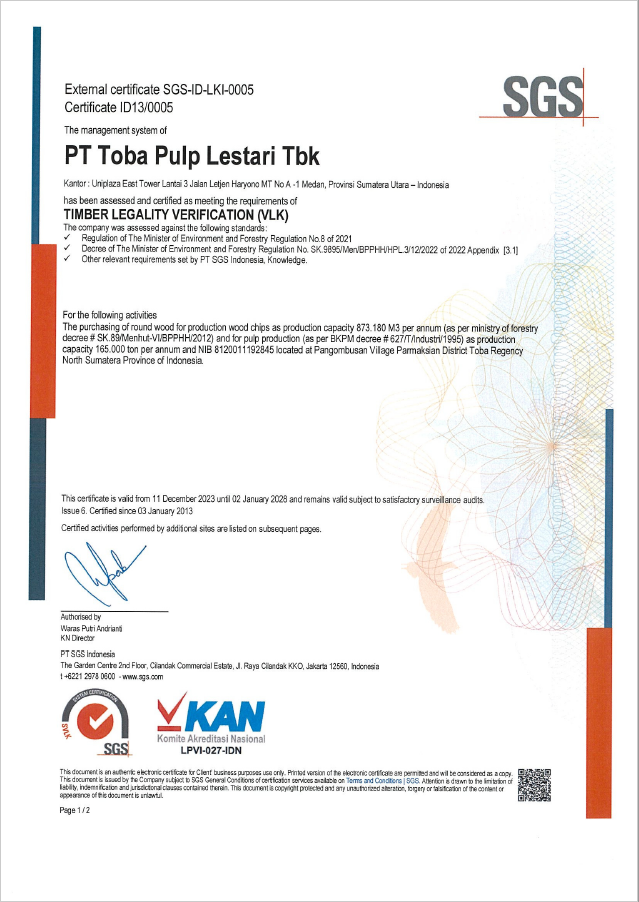

SVLK (Wood Material)

Timber Legality Verification (VLK) Certification from SGS Certification Body for the scope of activities: Purchasing raw material round logs for wood chips industry capacity production 873,180 ton per year accordance Industrial Primary Forest Product Permit Number 89/Menhut-VI/BPPHH/2012 issued Menteri Kehutanan revised of Number 627/T/Industri/1995 issued Keputusan Menteri Negara Penggerak Dana Investasi/Ketua Badan Koordinasi Penanaman Modal : 165,000 ton per year, obtained for the first time since 03rd January 2013. Has been Recertified up to the 3rd cycle at this point. Certificate Number: SGS-ID-LKI-0005, valid until 02nd January 2028.

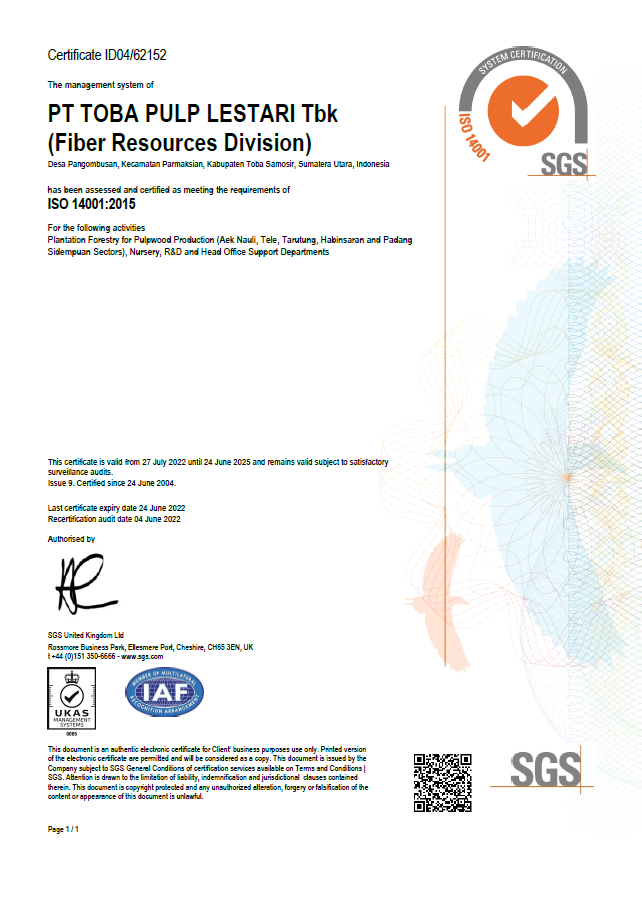

ISO 14001:2015 (Fiber Resource Division)

ISO 14001:2015 Environmental Management System certification from the SGS Certification Agency for the scope of activities: Plant Planting for pulpwood production (Aek Nauli, Tele, Tarutung, Habinsaran, and Padang Sidempuan Sectors), Nursery, R&D and Head Office Support Departments which was obtained first since June 24 2004. Has been Re-Certified up to the 6th Cycle at this time. Certificate Number: ID04/62152, valid until 24 June 2025.

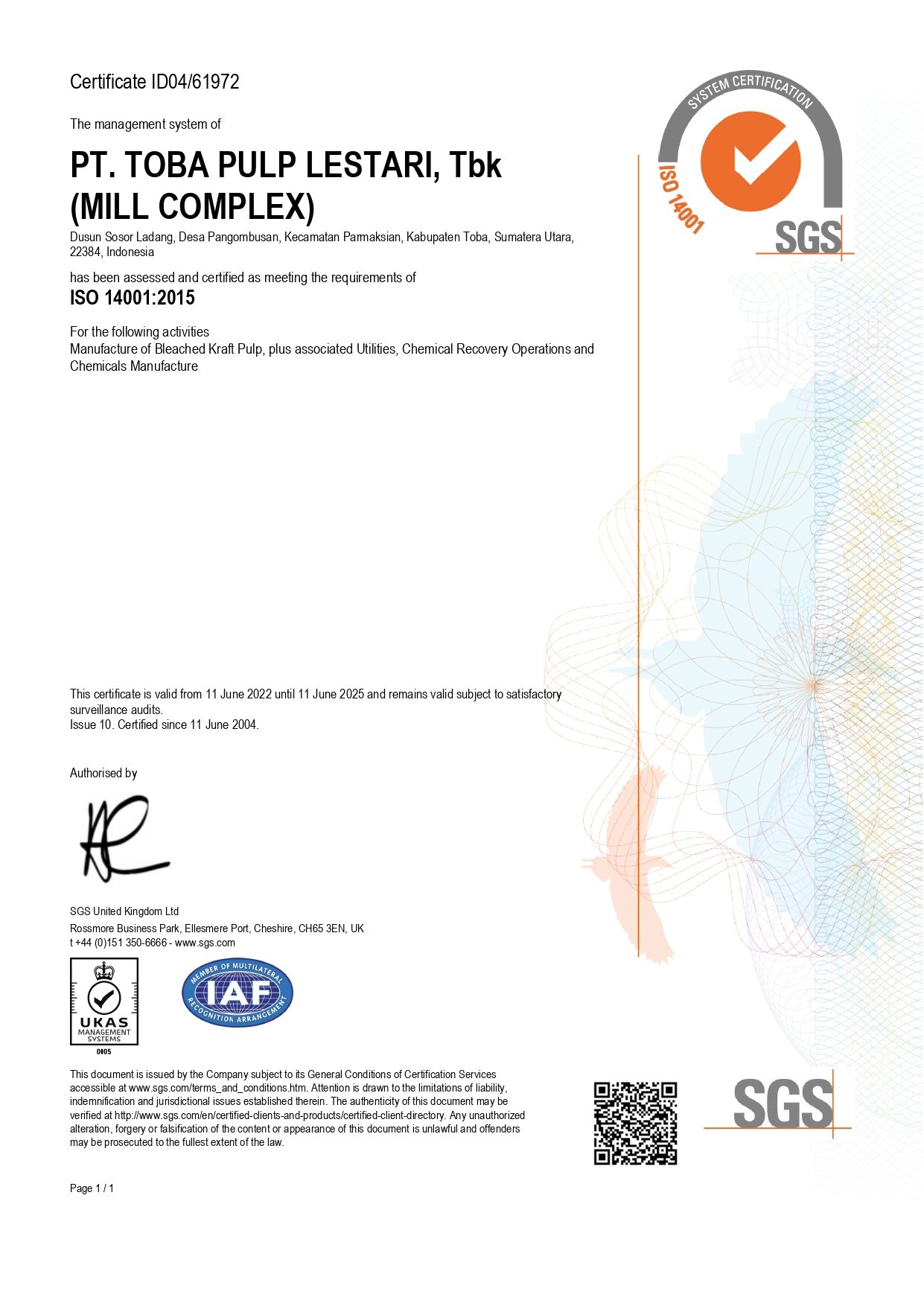

ISO 14001:2015 (Manufacture of Bleached Kraft Pulp)

ISO 14001:2015 Certification of Environmental Management System from SGS Certification Body for the scope of activities: Manufacture of Bleached Kraft Pulp, Plus Associated Utilities, Chemical Recovery Operation and Chemical Manufacture, obtained for the first time since 11th June 2004. Has been Recertified up to the 7th cycle at this point. Certificate Number: ID04/61972, valid until 11th June 2025

ISO 45001 (Toba Fiber Division)

ISO 45001:2018 Occupational Health and Safety Management System (K3) certification from the SGS Certification Agency for the scope of activities: Plant Planting for pulpwood production (Aek Nauli, Tele, Tarutung, Habinsaran, and Padang Sidempuan Sectors), Nursery, R&D and Head Office Support Departments obtained for the first time since March 30 2021. Have been Re-Certified up to the 5th Cycle at this time. Certificate Number: ID21/05655, valid until March 30, 2027

ISO 9001

ISO 9001:2015 Certification of Quality Management System from SGS Certification Body for the scope of activities: Manufacture of Bleached Kraft Pulp, Plus Associated Utilities, Chemical Recovery Operation and Process Chemical Manufacture, Additional Facilities: Head Office & Sales Admin Office Medan and Belawan Warehouse, obtained for the first time since 30th September 2005. Has been Recertified up to the 7th cycle at this point. Certificate Number: ID05/00658, valid until 30th September 2026

SMK3 Award

SGS ISO 45001

SGS ISO 9001

SGS ISO 14001

SVLK

PEFC Certified

PROPER

INDONESIA LEGAL WOOD FOREST MANAGEMENT UNIT

INDONESIA LEGAL WOOD OUTGROWER SCHEME